In 1963, Anthony Giorgio was working at a fastener company when he thought, “I could do this better.” He and a coworker formed All State Fastener (ASF), opening the company’s first location in Highland Park. According to the company’s history, “four employees worked long hours to keep up with the workload and used practical jokes and all-night card games to keep spirits high.”

Nearly 60 years later, ASF has become a renowned global fastener supplier and operates as a second-generation family-owned business with Tony Giorgio, Nick Giorgio and Paula Giorgio as owners. The company supplies fasteners for the automotive, construction, aerospace, and medical industries and recently received the General Motors Supplier of the Year Overdrive Award.

Family comes first

Lauren Hicks is manager, Culture and Communications for ASF and granddaughter of Anthony Giorgio. She said the company is something her entire family has grown up with. Family members now working alongside her at ASF include Lauren’s immediate family as well as her extended family.

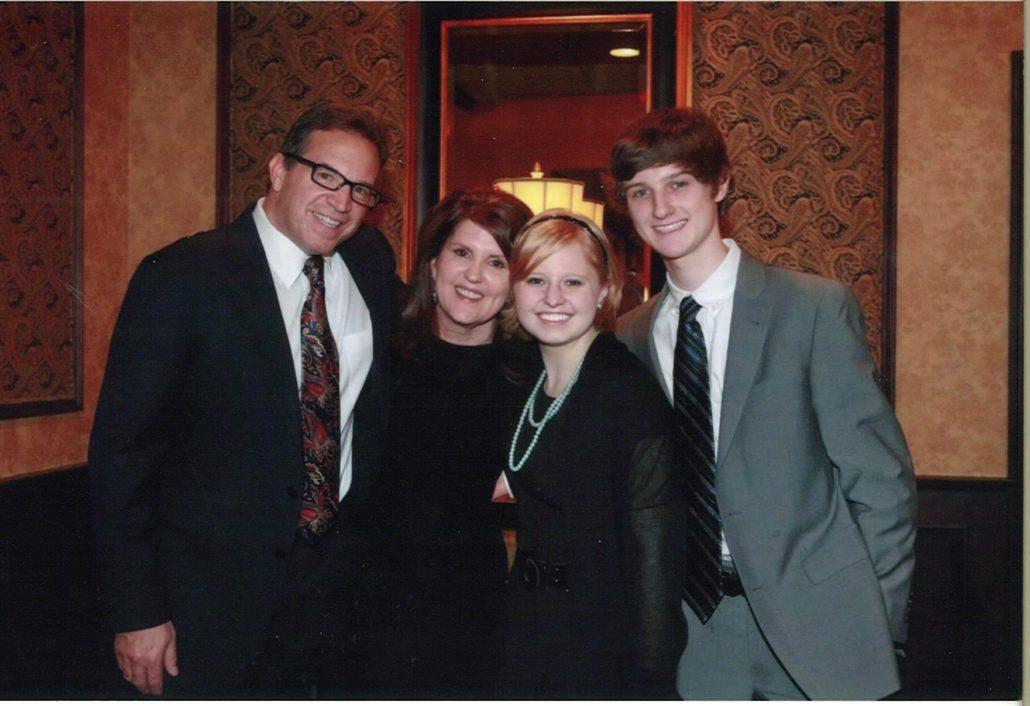

From left to right: Lauren Hicks’s dad, Tony Giorgio, ASF President; her mom, Christine; herself; and her brother, Tony.

“Being a family-owned company is definitely unique,” said Hicks. “I’ve worked at a variety of places, mostly bigger companies, and it’s a very different dynamic. My dad wanted me to experience other work environments so I could learn and grow before starting at ASF full-time.”

Hicks said work-life balance is a top priority at ASF. Since time spent with each other is important to her family, they understand that family comes first for their employees. But ASF has also created a family of its own.

“We’re very tightly knit,” said Hicks. “Everyone kind of feels like family – even those who aren’t related. I think a lot of it has to do with people who have been here for a while, some for more than 50 years. I feel really blessed to get to spend that time with my family and those who are close to us. A lot of people don’t get that opportunity.”

A sustainable future

As a family-owned company, creating a cleaner world for future generations is a top priority for ASF. The company has partnered with DTE to implement a number of energy efficiency measures, which are expected to result in savings of around 30-50% of ASF’s total energy use. These initiatives complement other steps the company has taken to reduce its environmental footprint, such as minimizing paper, using electric forklifts instead of gas, and a host of other programs.

ASF’s founder and Lauren Hicks’s grandfather, Anthony Giorgio, on the night of ASF’s 50th anniversary celebration in 2013.

ASF also recently enrolled in DTE’s MIGreenPower program, one of the largest voluntary renewable energy programs in the country, to attribute a percentage of ASF’s electricity use to DTE’s wind and solar parks. The company has enrolled at 25%, which has the environmental benefit equivalent to avoiding the greenhouse gas emissions from driving a passenger car 204,822 miles each year.*

“We want to be ahead of the game when it comes to sustainability,” Hicks said. “It’s the right thing to do and enrolling in MIGreenPower is such a simple step. It was so convenient for us since the DTE team takes care of everything – it makes enrolling a no-brainer. The energy efficiency opportunities through DTE also save ASF time and money, so it’s a win-win to be more environmentally conscious.”

In the future, ASF plans to implement more sustainability initiatives and continue to reduce their environmental impact.

“We’re always working to improve our processes,” said Hicks. “We’re trying to be conscious of our impact – it’s not just about money or efficiency – there’s a lot of benefits that come from being more sustainable.”

*Avoided emissions and equivalencies are based on the Environmental Protection Agency equivalencies calculator at epa.gov/energy/greenhouse-gas-equivalencies-calculator.