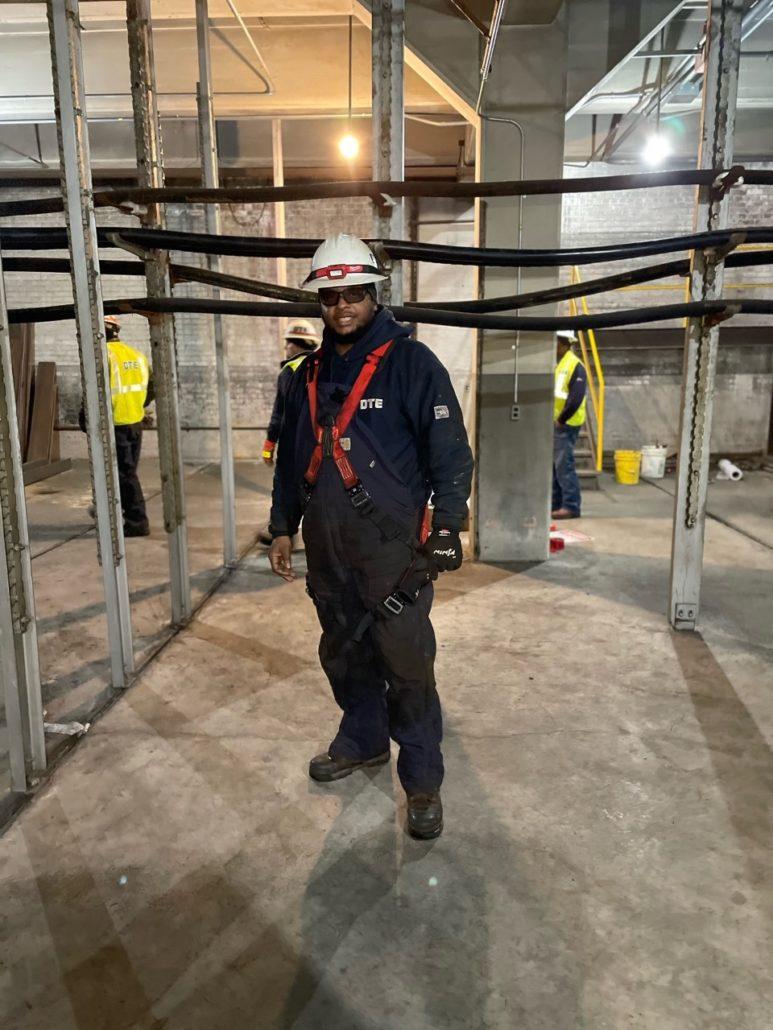

Whether it’s sunny, raining or snowing, you can count on cable pullers to keep your electricity running. Here’s what a typical day is like for Antoine, one of our many dedicated cable pullers.

Schedule

5:30 A.M. Antoine wakes up, knowing he has an essential role in helping DTE power your home.

6:37 A.M. He drops off his three kids to school before heading off to work as a cable puller.

7:30 A.M. He reports to his assigned service center where he attends a morning meeting, reviews safety protocols and gets his route for the day. He works with a team of three to six cable pullers to meet the day’s objectives.

8:30 A.M. He drives to a job site where he will either be installing or removing an underground cable: a challenging task which requires him to work in the tight, confined space of an electrical man hole.

Late afternoon: Antoine finishes his shift unless a high priority job requires him to work overtime. Cable pullers can work from eight-hour to 24-hour shifts to maintain electrical reliability for the community.

Off the clock

Although he takes off his hard hat when he gets home, he wears many other hats in his spare time. He splits his time between coaching his son’s kindergarten basketball league and being a “cheer dad,” supporting his two daughters at cheerleading competitions. Enjoying his time with his family is most important to him.

Passion meets challenge

Being out in the elements is what drew Antoine to this career. Besides appreciating the job’s physical demands, he also enjoys the mentally challenging aspects such as coming up with ways to safely rig a manhole. His other responsibilities include operating several types of trucks such as a cable hauler which carries anywhere from 6,000 to 7,000 pounds of cable, or a rodder which pulls cable through manhole ducts.

Environmental Impact

As someone who enjoys the outdoors, Antoine is proud to be working towards reducing the company’s carbon footprint. One initiative DTE cable pullers take part in is replacing aged paper and lead cable with ethylene propylene rubber cable which is a more environmentally friendly material to have underground. This improves reliability for customers while promoting practices that are better for the earth.